ORIGINAL ARTICLE

The effect of composite thickness as thermal insulation roof coating on room temperature reduction

El efecto del grosor del compuesto como revestimiento del tejado aislante térmico en la reducción de la temperatura ambiente

Redi Bintarto1 ![]() *, Anindito Purnowidodo1

*, Anindito Purnowidodo1 ![]() *, Djarot B. Darmadi1

*, Djarot B. Darmadi1 ![]() *, Teguh Dwi Widodo1

*, Teguh Dwi Widodo1 ![]() *

*

1Universitas Brawijaya. Faculty of Engineering, Department of Mechanical Engineering. Malang Indonesia.

Cite as: Bintarto R, Purnowidodo A, Darmadi DB, Widodo TD. The effect of composite thickness as thermal insulation roof coating on room temperature reduction. Salud Cienc. Tecnol. 2022;2(S2):192. https://doi.org/10.56294/saludcyt2022192

Submitted: 28-11-2022 Revised: 12-12-2022 Accepted: 20-12-2022 Published: 31-12-2022

ABSTRACT

The increasingly widespread use of galvanized roofs certainly has an effect on the occupants in the room below. Among them is a hot room temperature. For that reason, it is necessary to make new discoveries in the field of composites of natural materials to overcome them because most natural materials, especially natural stone, have low thermal conductivity, which means they can inhibit heat propagation. This study sought to ascertain how much andesite natural stone powder, combined with epoxy, can lower the room temperature when it is layered on a galvanized roof. Different amounts of natural stone powder applied to a galvanized roof results in different thermal conductivities. The temperature readings were taken at a height of 20 cm above the roof, right at the bottom galvanic, as well as the temperature in the room below. Our results showed that adding andesite natural stone powder to the roof was able to lower the room temperature, and the thicker the composite layer in coating the galvanized roof, the lower the room temperature under the roof.

Keywords: Natural Stone; Composite; Roof Technology; Temperature Reducer; Roof Coating; Galvanize.

RESUMEN

El uso cada vez más extendido de tejados galvanizados tiene sin duda efectos sobre los ocupantes de la habitación de abajo. Entre ellos se encuentra una temperatura ambiente caliente, para ello es necesario hacer nuevos descubrimientos en el campo de los compuestos de materiales naturales para superarlos, porque la mayoría de los materiales naturales, especialmente la piedra natural, tienen baja conductividad térmica, por lo que pueden inhibir la propagación del calor. El objetivo de este estudio era determinar en qué medida la aplicación de polvo de piedra natural de andesita, mezclado con epoxi, puede reducir la temperatura ambiente cuando se coloca en capas sobre un tejado galvanizado. La aplicación de polvo de piedra natural en el tejado galvanizado con diferentes cantidades provoca diferentes conductividades térmicas. La temperatura se mide a una altura de 20 cm por encima del techo, justo en la parte inferior galvánica, y la temperatura en la habitación de abajo. Los resultados mostraron que la adición de polvo de piedra natural andesita en el techo fue capaz de reducir la temperatura ambiente, y cuanto más gruesa es la capa de material compuesto en el recubrimiento del techo galvanizado, afecta a la disminución de la temperatura ambiente bajo el techo.

Palabras clave: Piedra Natural; Compuesto; Tecnología de Tejados; Reductor de Temperatura; Revestimiento de Tejados; Galvanizado.

INTRODUCTION

According to global energy consumption data, earthlings living in the house have consumed massive amounts of energy produced around the world. Mostly used 40 % of total energy, resulting in 30 % of exhaust gas in the form of CO2. This building spends that energy to provide comfort related to air conditioning.(1) The roof is the most important factor that affects the temperature in a room, causing the need for air conditioning in it, of the many parameters that affect the temperature in the room. The roof has a large influence on the room temperature, which can reach 70 %.(2)

Many people prefer metal roofs because of the low installation costs and lighter weight when compared to cast-iron or earthen roofs; the overall installation cost is much cheaper and the installation is faster. Metal roofs, on the other hand, have some disadvantages, including high temperatures below due to their high thermal conductivity.(3) A study stated that houses in Ecuador have a hotter room temperature due to the use of metal roofs. As a consequence, air conditioning is needed to reduce room temperature.(4)

The research challenge of keeping the room temperature cool when using metal roofs is still open. If the number of occupants in the house increases, so will the air temperature in the room. One of the technologies needed is roof coating technology. Metal roofs must be treated with the aforementioned coating to reduce heat propagation.(5) Roof coating technology, in addition to lowering room temperature, can reduce air conditioner ignition and electrical energy consumption.(6)

One of the methods to reduce room temperature with a metal roof is to make a roof layer with a composite coating. The thermal conductivity of the additional material in the form of the coating must be kept low, in order that when it is added to the total thermal conductivity of the metal and its coating, a lower level of thermal conductivity is produced. One of them is the use of natural materials.(7) Ceramic is a natural material with low thermal conductivity. Residential buildings use ceramics as a thermal insulation material aimed at reducing indoor heating due to hot weather because it has low thermal conductivity.(8)

Coating natural materials on the roof requires a matrix or adhesive, and the material that is widely used to glue natural materials is epoxy. The use of epoxy will be very helpful in terms of attaching natural materials to metal roofs. The use of epoxy and natural material composites coated on metal roofs will improve the thermal, mechanical, and electrical properties of the roof.(9)

One of the materials that is widely used in buildings due to its thermal capabilities is natural stone. In addition to its attractive color when used for building ornaments, natural stone also has the ability to act as a heat insulator. Natural stone has a low level of thermal conductivity when compared to metals.(10) For this reason, the use of metal roofs requires additional coatings that can reduce heat in the space in order that the coatings applied to the roof will reduce heat transfer that occurs on the roof.(11)

The important point in this study is that the use of coatings containing natural ingredients can reduce room temperature; however, it is critical to investigate how far the coating can reduce room temperature. One of the parameters that must be investigated is the effect of the thickness of the composite layer coated with natural materials on a metal roof on the level of room temperature reduction.

METHODS

Experimental models.

Experiments were conducted for sixteen days during May and June 2022. Starting at 10 a.m. in the hot climate of Malang (Latitude: -7° 58' 46,92" S & Longitude: 112° 37' 49,44" E), East Java province, Indonesia. Six identical miniature rooms were manufactured for these experiments.

Miniature box A: a reference box consisting of the box with a galvanized roof without coating. Miniature box B: consists of a box with an epoxy coating. Box miniature C-F: consist of a box with galvanized composite, mixing natural stone powder and epoxy for the first test, and different powder dimensions for the second test.

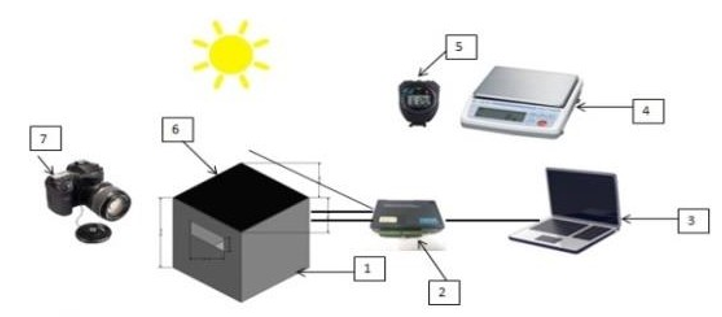

Each miniature room box was made of wood with a dimension of 500 mm x 500 mm x 500 mm and with a 2 x 250 mm x 100 mm ventilation. Around the box were attached four thermocouples to measure the temperature, which were placed as follow: a=20 cm above roof; b=above (stick on) roof or composite; c=under (stick on) the galvanized material; and d= room temperature - 10 cm height from the floor (see experiment box). The composite layer was made by mixing natural stone powder and epoxy in the same ratio.

Epoxy has a ratio of hardener to epoxy of 1:2; after the epoxy mixture is ready, then the natural stone powder is added into the epoxy hardener mixture to ensure the natural stone powder can be evenly distributed. In particular, stirring is done with a mixer set to 942 rpm for 5 minutes. The mixture was then poured onto the galvanized sheet to make sure it covered the entire galvanized surface evenly. After the composite layer was dry, a specimen was used for the temperature reduction test. The method of making these specimens can be seen in figure 1.

1. Glass 2. 500mm x 500mm acrylic 3. Galvanic plate 4. Paintbrush 5. Specimen (galvanic epoxy coat)

Figure 1. Schematic View of specimen preparation method

Measurement Devices

To ensure the validity of the data obtained, the thermal conductivity was measured by Tokyo meter co.ltd. where there are 12 thermocouples, of which 6 sensors are at the top of the specimen and the other 6 sensors are at the bottom of the specimen. Tests were carried out on all materials, including galvanizing without coating, galvanizing with only epoxy coating, as well as specimens with mixtures of other natural materials.

Figure 2. Thermal conductivity measuring device

The test was carried out for the first time by testing the composition with xrf. After obtaining the rock composition, a thermal conductivity specimen was created by forming a test specimen to the size of the thermal conductivity test tool. The next test was the macro test, where the specimen was photographed as a whole to determine the level of distribution of rock powder and its color. for the temperature drop test s carried out by placing a galvanized specimen that has been coated with a composite on a miniature wooden box measuring 500 x 500 x 500 mm. As a miniature form of a house, the box is given a ventilation of 20 % of the floor area (Regulation of the Minister of Health of the Republic of Indonesia Number 1077 of 2011 concerning Guidelines for Air Conditioning for Sanitizing House Rooms).(5) The ventilation measured 100 x 250 mm and there were 2 in front and back (figure 2). The equipment used can be seen clearly in Figure 3. The miniature box was equipped with a thermocouple with placement according to the picture, where the purpose of choosing the location of this thermocouple is to find out the temperature with a position of 20cm above the roof, then right on the roof, under the roof, and the temperature of the room, where the room temperature is represented by a thermocouple with a position of 10cm from the floor. The schematic of the temperature testing device can be seen in Figure 2-5.

RESULT AND DISCUSSION

Analysis of natural stones composition

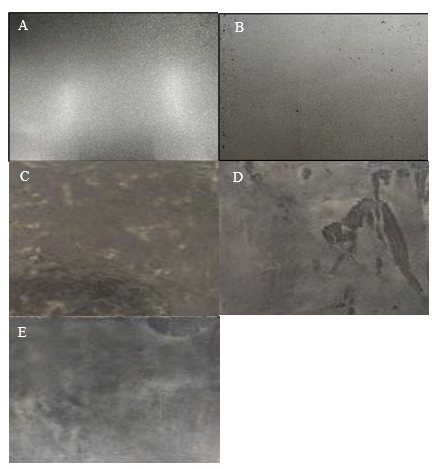

Macroscopic photos were taken to determine the level of distribution of natural stone powder on the specimen. Apart from that, from the macro photo, the color and distribution of the epoxy mixture and natural stone powder can be observed, where good conditions can occur if the coating is able to completely coat and cover all galvanized surfaces.

Figure 3. Experiment box

Figure 4. Experiment Tools (Temperature Data Mining)

1. Experiment box, 2. Data logger, 3. Computer, 4. Scales, 5. Stopwatch(timer), 6. Specimen (galvanic coated composite) 7. Camera

Figure 5. Schematic View of experimental

Figure 5 shows a photo of the coating specimen with variations in coating thickness on a galvanized roof. The three specimen images showed different distributions of natural stone grains, depending on whether the sequence of specimens could cover the galvanized surface or not. The three specimens (C,D,E) had epoxy resin and natural stone in the same ratio but had different total weights: 300 grams, 400 grams, and 500 grams.

Figure 6. Macro photos of galvanized roof coating specimens: (A) Galvanis Plate; (B) Epoxy Coated; (C) Epoxy and Andesit stone 1,26mm thickness; (D) Epoxy and Andesit stone 1,70mm thickness; (E) Epoxy and Andesit stone 2,3mm thickness.

In figure 6 (A), andesite stone cannot cover the entire galvanized surface (50 %) because the lower the total weight, the more difficult it is for the coating to cover the entire surface when compared to the grain size below it.

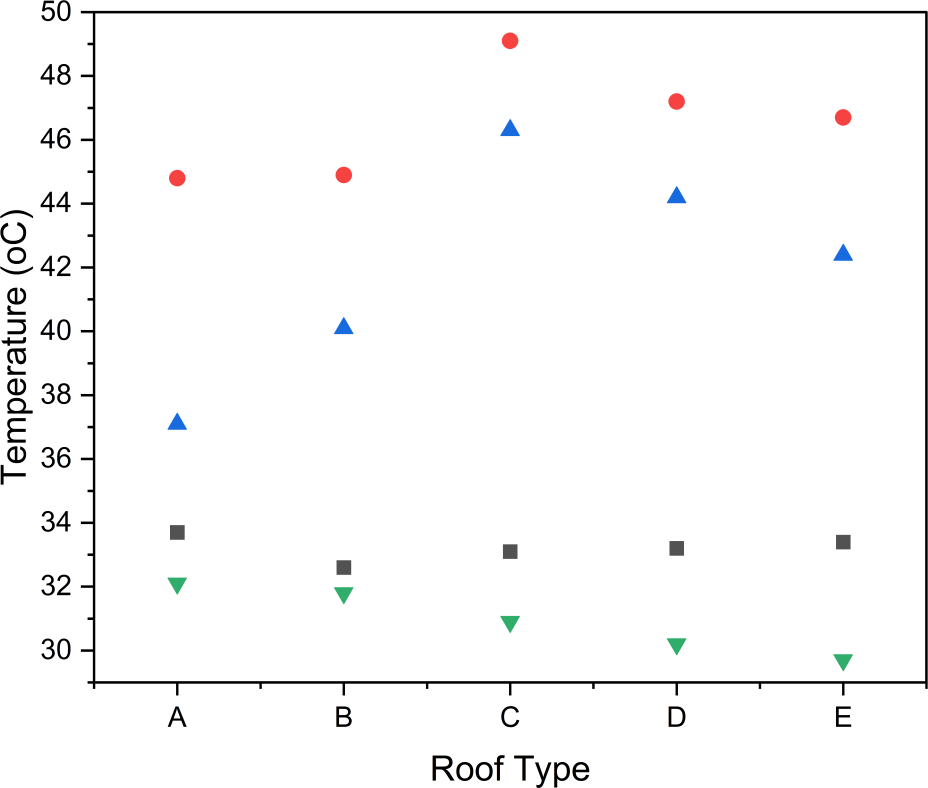

The temperature taking points are at 4 points, namely, the outdoor temperature, the coating surface temperature, the galvanic surface temperature, and the galvanic interior/room temperature.

At the temperature measurement of 4 points, the highest temperature on the galvanized coating. This is because the surface of the roof coating experiences the sun radiation directly, consequently the temperature of the roof coating is the highest. Then followed by the temperature of the galvanic roof due to conduction from the coating to the galvanic. Then followed by the temperature of the sun as the input heat. And the last one is the lowest room temperature because it is not exposed to direct sunlight. Each data is taken within 10 minutes and produces different T (figure 7).

(A) Galvanic Plate (B) Epoxy Coated (C) Epoxy and Andesite stone 1,26mm thickness

(D) Epoxy and Andesite stone 1,70mm thickness (E) Epoxy and Andesite stone 2,3mm thickness

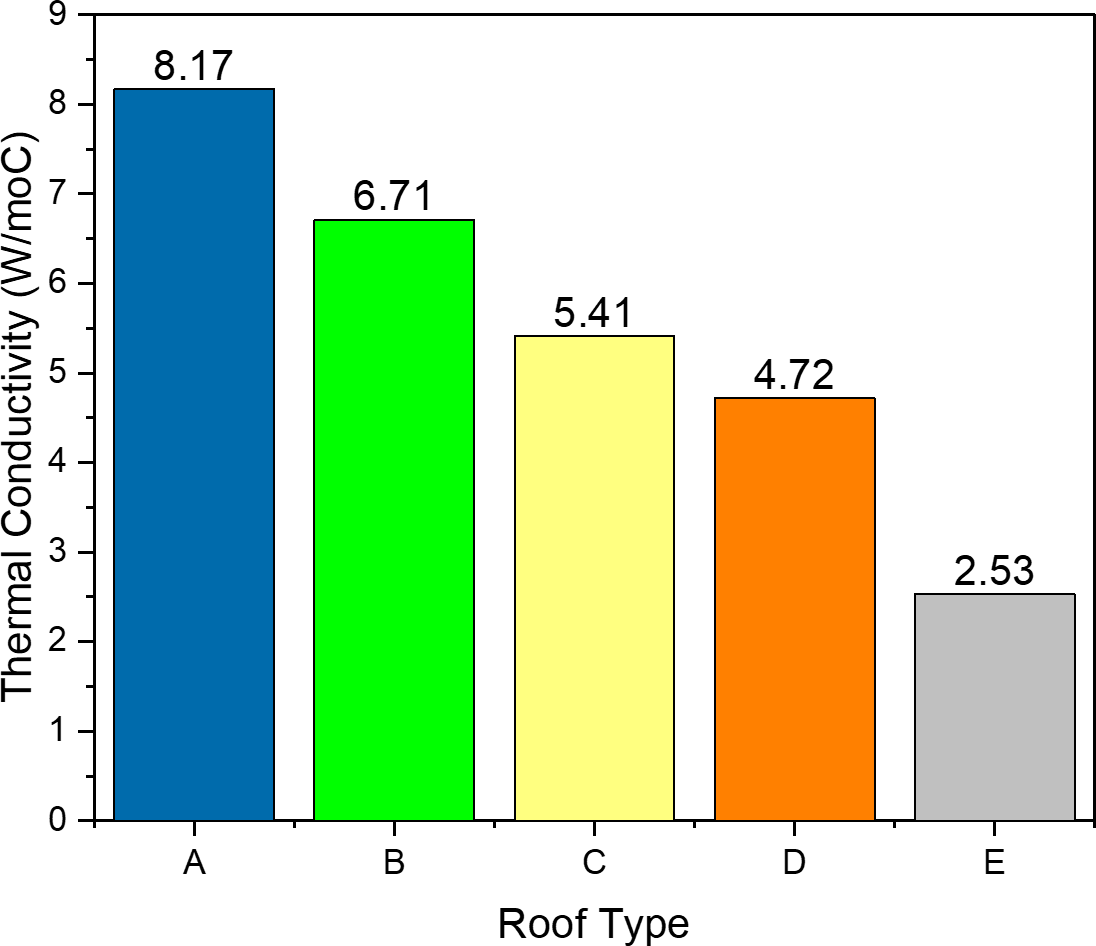

Figure 7. Roof type and average thermal level

Figure 8. Roof type and average thermal level

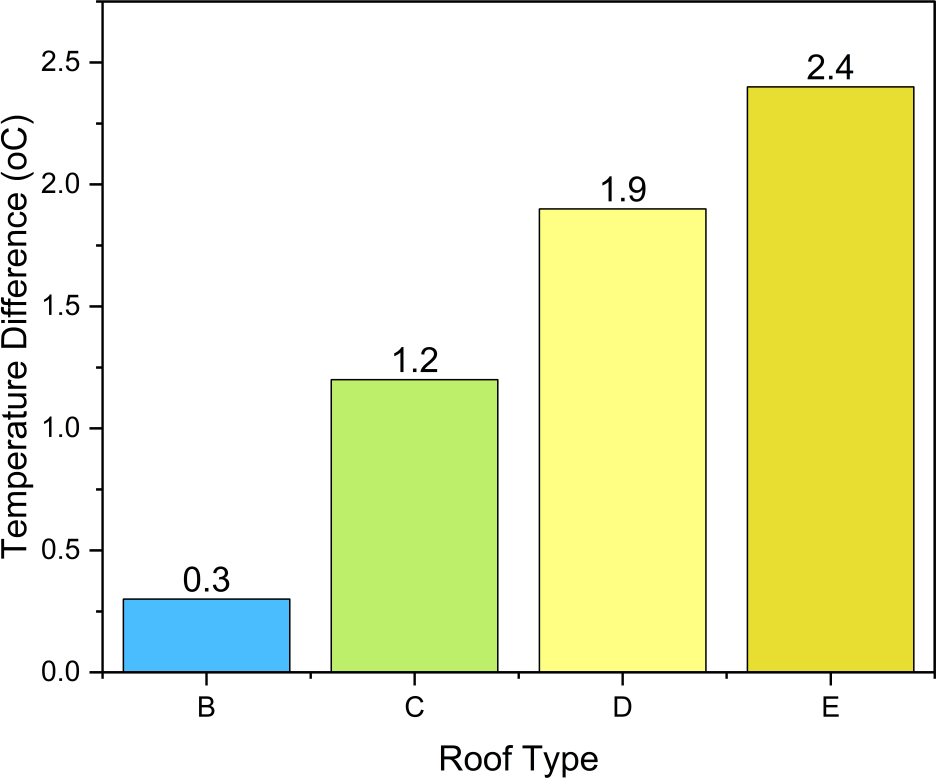

Figures 8 and 9 shows a relationship between variations in coating thickness and a decrease in room temperature.

The relationship between thickness variations without coating (1,26 mm, 1,70 mm, and 2,3 mm) and a decrease in temperature can be seen. The galvalume without coating experienced an average decrease of 2,743°C; the coating with a thickness of 1,26 mm experienced a decrease of 4,178°C; the coating with a thickness of 1,70 mm experienced a decrease of 4,438°C; and the coating with a thickness of 2,30 mm experienced a decrease of 4,889 °C.

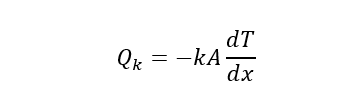

The highest temperature drop was at 2,30 mm and the lowest was at galvalume without coating in accordance with our hypothesis (figure 8). The hypothesis is formulated such that the difference in coating thickness will produce different values of the temperature difference (Δt). The greater the thickness of the coating, the longer the heat passes through the coating according to the thermal conductivity formula, namely:

With:

Q = The rate of Heat Transfer (KJ/s,W)

k = Thermal Conductivity of materials (W/m°C) A = Area - Cross-sectional (m²)

dT = Difference of Temperature (°C) dX = Distance (thick of specimen) (m) T = Temperature (°C)(6)

Where the thickness (dx) is the denominator, the greater the thickness value, the more difficult it is for heat to propagate. Consequently, the lower room temperature is more difficult to heat if the coating is thicker. We could infer that the thickness of three layers would be the best because it has the highest thickness. However, the roof becomes heavier as the layer thickness increases. Consequently, when compared based on thickness, the 2,30 mm thick coating will have the highest temperature drop.

Figure 9. Roof type and temperature difference

CONCLUSION

The thickness of the specimen coating affects thermal conductivity; the thicker the coating, as calculated by the thermal conductivity formula and proven by direct testing, the lower the level of thermal conductivity because the thermal conductivity of the composite layer is far below galvanic. The lowest value of thermal conductivity is galvanized with a thickness of 2,30 mm and the highest is galvanized without coating. The conductivity was sequentially (8,067 Kcal/mhr °C), (5,389 Kcal/mhr °C), (4,634 Kcal/mhr °C), (2,449 Kcal/mhr °C). This result is also in accordance with the temperature drop test where the thicker the coating, the greater the temperature drop. Where sequentially obtained T galvalume without coating is 2,743 oC, on coating with a thickness of 1,26 mm it is 4,178 oC, on coating with a thickness of 1,70 mm it is 4,438 °C, on coating with a thickness of 2,30 mm it is 4,889 °C. This proves that the thicker the composite layer used to coat the galvanized roof, will cause a decrease in the temperature of the room under the roof.

BIBLIOGRAPHIC REFERENCES

1. Yang L., Yan H., Lam J.C. Thermal comfort and building energy consumption implications – A review. Applied Energy 2014;115:164-173. doi:10.1016/j.apenergy.2013.10.062

2. Al-Obaidi K.M., Ismail M., Abdul Rahman A.M. Passive cooling techniques through reflective and radiative roofs in tropical houses in Southeast Asia: A literature review. Frontiers of Architectural Research 2014;3(3):283-297. doi:10.1016/j.foar.2014.06.002

3. Yuliani,S., Hardiman G., Setyowati E., Setyaningsih W., Winarto Y. Thermal behaviour of concrete and corrugated zinc green roofs on low-rise housing in the humid tropics. Architectural Science Review 2020. doi:10.1080/00038628.2020.1751054

4. Litardo J., Macías J., Hidalgo-León R., Cando M.G., Soriano G. Measuring the Effect of Local Commercial Roofing Samples on the Thermal Behavior of a Social Interest Dwelling Located in Different Climates in Ecuador. Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2019;6:V006T06A047. doi:10.1115/IMECE2019-11472

5. Vengala J., Dharek M.S., Sachin D., Ghanashyam T.B. Thermal analysis of building model with acrylic and aluminium based roof coating materials. Materials Today: Proceedings 2021;47(13):3787-3793. doi:10.1016/j.matpr.2021.03.008

6. Rahmani F., Robinson M.A., Barzegaran M.R. Cool roof coating impact on roof-mounted photovoltaic solar modules at texas green power microgrid. International Journal of Electrical Power & Energy Systems 2021;130:106932. doi:10.1016/j.ijepes.2021.106932

7. Muthukumar K., Sabariraj R.V., Dinesh Kumar S., Sathish T. Investigation of thermal conductivity and thermal resistance analysis on different combination of natural fiber composites of Banana, Pineapple and Jute. Materials Today: Proceedings 2020;21(1):976-980. doi:10.1016/j.matpr.2019.09.140

8. Hu J.J., Huang Y., Zeng X., Li Q., Ren L., Sun R., Xu J.B., Wong C.P. Polymer composite with enhanced thermal conductivity and mechanical strength through orientation manipulating of BN. Composites Science and Technology 2018;160:127-137. doi:10.1016/j.compscitech.2018.01.045

9. Saba N., Jawaid M., Alothman O.Y., Paridah M., Hassan A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. Journal of Reinforced Plastics and Composites 2016;35(6):447-470. doi:10.1177/0731684415618459

10. Tufan B., Kun M. Thermal Insulation Performance and Thermal Conductivity Evaluation of Natural Stones by Infrared Thermography. Proceedings of the International Conference on Mining, Material and Metallurgical Engineering 2014;Paper No. 62.

11. Yew MC, Ramli Sulong NH, Chong WT, Poh SC, Ang BC, Tan KH. Integration of thermal insulation coating and moving-air-cavity in a cool roof system for attic temperature reduction. Energy Conversion and Management. 2013;75:241-248. doi:10.1016/j.enconman.2013.06.024

12. Popov YA, Pribnow FC, Sass JH, Williams CF, Burkhardt H. Characterization of rock thermal conductivity by high-resolution optical scanning. Geothermics. 1999;28:253-276.

13. Afandi YK, Arief IS, Amiadji. Analisa Laju Korosi pada Pelat Baja Karbon dengan Variasi Ketebalan Coating. 2015;4(1).

14. Tufan B, Kun M. Thermal Insulation Performance and Thermal Conductivity Evaluation of Natural Stones by Infrared Thermography. Proceedings of the International Conference on Mining, Material and Metallurgical Engineering. 2014; Paper No. 62.

15. Yew MC, Ramli Sulong NH, Chong WT, Poh SC, Ang BC, Tan KH. Integration of thermal insulation coating and moving-air-cavity in a cool roof system for attic temperature reduction. Energy Conversion and Management. 2013;75:241-248. doi:10.1016/j.enconman.2013.06.024

16. Bobde SA, Kshirsagar SD. Improving The Sink Roll Life In Galvalume Using Material AT101 & The variousThermal-Spray Coating on SS3l6L Roll Surface. International Journal of Soft Computing and Engineering. 2013;3(1):282-286.

17. Lopez-Buendia AM. Natural stone reinforcement of discontinuities with resin for industrial processing. Journal Engineering Geology. 2013.

18. Tiskatine R, Oaddi R, El Cadi RA, Bazgaou A, Bouirden L, Aharoune A, Ihlal A. Suitability And Characteristics Of Rocks For Sensible Heat Storage In CSP Plants. Solar Energy Materials And Solar Cells. 2017;169:245-257.

19. Abe H, Abe I, Sato K, Naito M. Dry powder processing of fibrous fumed silica compacts for thermal insulation. J Am Ceram Soc. 2005;88(5):1359-1361.

20. Abe I, Sato K, Abe H, Naito M. Formation of porous fumed silica coating on the surface of glass fibers by a dry mechanical processing technique. Adv Powder Technol. 2008;19(4):311-320.

21. Adamczyk Janusz., Dylewski Robert. The Impact of Thermal Insulation Investments on Sustainability in The Construction Sector. Renewable and Sustainable Energy Review. 2017;80:421- 429, Elsevier.

22. Benane, B. G.P. Baeza, B. Chal, L. Roiban, S. Meille, C. Olagnon, B. Yrieix, G. Foray. Multiscale structure of super insulation nano-fumed silicas studied by SAXS, tomography and porosimetry. Acta Mater. 2019;168:401–410.

23. Charqui, Z. Lahcen El Moutaouakil, Mohammed Boukendil, Rachid Hidki. Numerical study of heat transfer in a tall, partitioned cavity confining two different fluids: Application to the water Trombe wall. International Journal of Thermal Sciences. 2022;171:107266.

24. Culcasi, José Daniel, Elsner, Cecilia Inés, di Sarli, Alejandro Ramón. Effect of Zinc Crystals Size on Galvanized Steel Deformation and Electrochemical Behavior. Materials Research. 2009;12(3):273-279.

25. Du, H. Shijie Wang, Yiqiang Xing, Xiang Li, Mengbo Pan, Wenhao Qi, Chengliang Ma. The dual effect of zirconia fiber on the insulation and mechanical performance of the fumed silica-based thermal insulation material. Ceramics International. 2022;48(5):6657-6662.

26. Feng, J. Y. Yan, D. Chen, W. Ni, J. Yang, S. Ma, W. Mo. Study of thermal stability of fumed silica based thermal insulating composites at high temperatures. Compos. B Eng. 2011;42(7):1821–1825.

27. Feng,J. D. Chen, W. Ni, S. Yang, Z. Hu. Study of IR absorption properties of fumed silica- opacifier composites, J. Non-Cryst. Solids. 2010;356(9–10):480–483.

28. Lei,Y. X. Chen, H. Song, Z. Hu, B. Cao, 2017. Improvement of thermal insulation performance of silica aerogels by Al2O3 powders doping, Ceram. Int. 2017;43(14):10799–10804.

29. Lian, T.W. A. Kondo, T. Kozawa, T. Ohmura, W.-H. Tuan, M. Naito. Effect of fumed silica properties on the thermal insulation performance of fibrous compact. Ceram. Int. 2015;41(8):9966–9971.

30. Liu, J., Moore, J. D., Skokov, K. P., Krautz, M., Löwe, K., Barcza, A., Gutfleisch, O. Exploring La(Fe,Si)13-based magnetic refrigerants towards application. Scripta Materialia. 2012;67(6):584–589. https://doi.org/10.1016/j.scriptamat.2012.05.039.

31. Mishra Subhash, Usmani J A, Varshney Sanjeev. Energy Saving Analysis in Building Walls Through Thermal Insulation System. International Journal of Engineering Research and Applications (IJERA). 2012;2(5):128-135.

32. Moritz, W., Yoshinobu, T., Finger, F., Krause, S., Martin-Fernandez, M., & Schöning, M. J. High resolution LAPS using amorphous silicon as the semiconductor material. Sensors and Actuators B: Chemical. 2004;103(1-2):436–441. http://doi.org/10.1016/j.snb.2004.04.073.

33. Peças, Paulo, Hugo Carvalho, Hafiz Salman, and Marco Leite. Natural Fibre Composites and Their Applications: A Review. Journal of Composites Science. 2018;2(4):66. https://doi.org/10.3390/jcs2040066.

34. Popov, Y.A., Pribnow, F.C., Sass, J.H., Williams, C.F., Burkhardt, H. Characterization of rock thermal conductivity by high-resolution optical scanning. Geothermics. 1999;28:253-276.

35. Reichenauer, G. U. Heinemann, H.P. Ebert. Relationship between pore size and the gas pressure dependence of the gaseous thermal conductivity, Colloids Surf. A Physicochem. Eng. Asp. 2007;300(1–2):204–210.

36. R. Tiskatine., R. Oaddi., R. Ait El Cadi., A. Bazgaou. L. Bouirden., A. Aharoune., A. Ihlal. Suitability and Characteristics of Rocks for Sensible Heat Storage in CSP Plants. Solar Energy Materials and Solar Cells. 2017;169:245-257.

37. Shafi,S. J. Tian, R. Navik, Y. Gai, X. Ding, Y. Zhao. Fume silica improves the insulating and mechanical performance of silica aerogel/glass fiber composite. J. Supercrit. Fluids. 2019;148 9–15.

38. Singh, T.N., Sinha, S., Singh, V.K. Prediction of thermal conductivity of rock through physicomechanical properties. Building and Environment. 2007;42:146-155.

39. Wang, H. M. Cao, H.-B. Zhao, J.-X. Liu, C.-Z. Geng, Y.-Z. Wang. Double-cross-linked aerogels towards ultrahigh mechanical properties and thermal insulation at extreme environment, Chem. Eng. J. 2020;399:125698.

40. Yang, W. Yingying Wang, Jiaping Liu. Optimization of the thermal conductivity test for building insulation materials under multifactor impact. Construction and Building Materials. 2022;332(2022):127380.

41. Haiyue Yang, Weixiang Chao, Xin Di, Zhaolin Yang, Tinghan Yang, Qianqian Yu, Feng Liu, Jian Li, Guoliang Li, Chengyu Wang. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage. Energy Conversion and Management. 2019;200(2019):112029. https://doi.org/10.1016/j.enconman.2019.112029.

42. Zhang, H. Chenyang Shang, Guihua Tang. Measurement and identification of temperature-dependent thermal conductivity for thermal insulation materials under large temperature difference. International Journal of Thermal Sciences. 2022;171:107261.

43. Zeng, S.Q. A. Hunt, R. Greif. Mean free path and apparent thermal conductivity of a gas in a porous medium. J. Heat Tran. 1995;117(3):758–761.

44. Zhou,T. X. Cheng, Y. Pan, C. Li, L. Gong, H. Zhang. Mechanical performance and thermal stability of glass fiber reinforced silica aerogel composites based on coprecursor method by freeze drying. ppl. Surf. Sci. 2018;437:321–328.

45. Zou, W. X. Wang, Y. Wu, L. Zou, G. Zu, D. Chen, J. Shen. Opacifier embedded and fiber reinforced alumina-based aerogel composites for ultra-high temperature thermal insulation. Ceram. Int. 2019;45(1):644–650.

CONFLICTS OF INTEREST

None.

FINANCING

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Redi Bintarto, Anindhito Purnowidodo, Djarot B. Darmadi, Teguh Dwi Widodo.

Methodology: Redi Bintarto, Anindhito Purnowidodo, Djarot B. Darmadi, Teguh Dwi Widodo.

Writing - Original Draft: Redi Bintarto, Anindhito Purnowidodo, Djarot B. Darmadi, Teguh Dwi Widodo.

Writing - Review & Editing: Redi Bintarto, Anindhito Purnowidodo, Djarot B. Darmadi, Teguh Dwi Widodo.